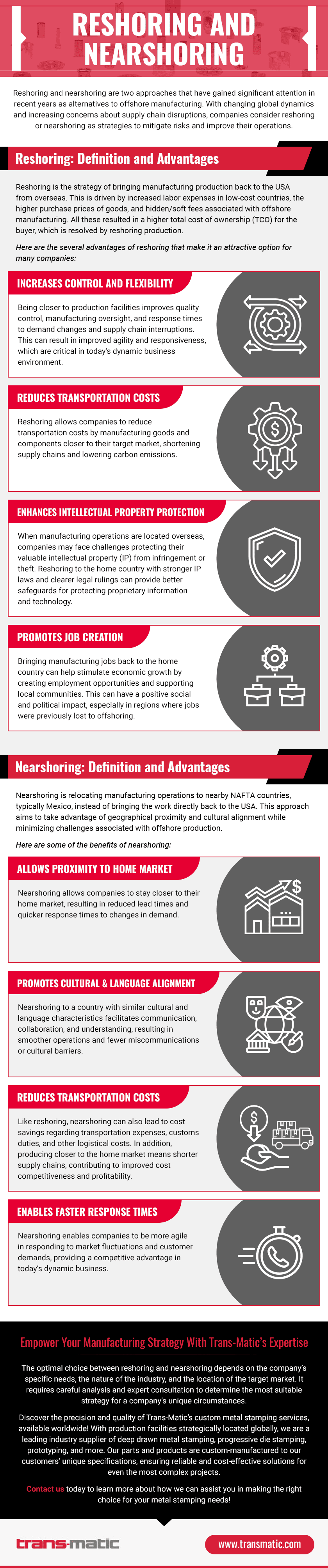

Reshoring and nearshoring are two approaches that have gained significant attention in recent years as alternatives to offshore manufacturing. With changing global dynamics and increasing concerns about supply chain disruptions, companies consider reshoring or nearshoring as strategies to mitigate risks and improve their operations.

This article will explore the advantages of reshoring and nearshoring. We will compare the two approaches to help businesses decide on the best approach for their manufacturing operations.

Reshoring: Definition and Advantages

Reshoring is the strategy of bringing manufacturing production back to the USA from overseas. This is driven by increased labor expenses in low-cost countries, the higher purchase prices of goods, and hidden/soft fees associated with offshore manufacturing. All these resulted in a higher total cost of ownership (TCO) for the buyer, which is resolved by reshoring production.

Here are the several advantages of reshoring that make it an attractive option for many companies:

Increases Control and Flexibility

Being closer to production facilities improves quality control, manufacturing oversight, and response times to demand changes and supply chain interruptions. This can result in improved agility and responsiveness, which are critical in today’s dynamic business environment.

Reduces Transportation Costs

Reshoring allows companies to reduce transportation costs by manufacturing goods and components closer to their target market, shortening supply chains and lowering carbon emissions.

Enhances Intellectual Property Protection

When manufacturing operations are located overseas, companies may face challenges protecting their valuable intellectual property (IP) from infringement or theft. Reshoring to the home country with stronger IP laws and clearer legal rulings can provide better safeguards for protecting proprietary information and technology.

Promotes Job Creation

Bringing manufacturing jobs back to the home country can help stimulate economic growth by creating employment opportunities and supporting local communities. This can have a positive social and political impact, especially in regions where jobs were previously lost to offshoring.

Nearshoring: Definition and Advantages

Nearshoring is relocating manufacturing operations to nearby NAFTA countries, typically Mexico, instead of bringing the work directly back to the USA. This approach aims to take advantage of geographical proximity and cultural alignment while minimizing challenges associated with offshore production.

Here are some of the benefits of nearshoring:

Allows Proximity to Home Market

Nearshoring allows companies to stay closer to their home market, resulting in reduced lead times and quicker response times to changes in demand.

Promotes Cultural and Language Alignment

Nearshoring to a country with similar cultural and language characteristics facilitates communication, collaboration, and understanding, resulting in smoother operations and fewer miscommunications or cultural barriers.

Reduces Transportation Costs

Like reshoring, nearshoring can also lead to cost savings regarding transportation expenses, customs duties, and other logistical costs. In addition, producing closer to the home market means shorter supply chains, contributing to improved cost competitiveness and profitability.

Enables Faster Response Times

Nearshoring enables companies to be more agile in responding to market fluctuations and customer demands, providing a competitive advantage in today’s dynamic business.

Empower Your Manufacturing Strategy With Trans-Matic’s Expertise

The optimal choice between reshoring and nearshoring depends on the company’s specific needs, the nature of the industry, and the location of the target market. It requires careful analysis and expert consultation to determine the most suitable strategy for a company’s unique circumstances.

Discover the precision and quality of Trans-Matic’s custom metal stamping services, available worldwide! With production facilities strategically located globally, we are a leading industry supplier of deep drawn metal stamping, progressive die stamping, prototyping, and more. Our parts and products are custom-manufactured to our customers’ unique specifications, ensuring reliable and cost-effective solutions for even the most complex projects.

Contact us today to learn more about how we can assist you in making the right choice for your metal stamping needs!