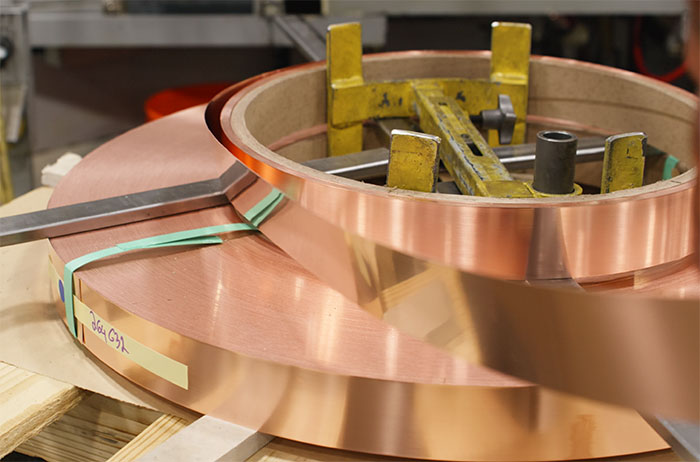

Material selection plays a major role in how stamped metal parts perform, last, and fit into an overall assembly. As a global metal stamping manufacturer, we work closely with our customers to identify the right material to improve strength, reduce waste, and simplify part finishing across deep draw metal forming, progressive die stamping, and transfer press stamping applications.

Where Metal Takes Shape

Family Owned,

Professionally Managed

Founded in 1968, Trans-Matic was the first deep draw metal stamping company in West Michigan. Starting out with only two presses, Pat Thompson built the company on a simple premise: to provide high-quality, reliable metal stamping of the highest caliber across a diversified market. That’s where our story begins.

Worldwide Industry Leader in Metal Stamping

Monterrey, Mexico

55,000 Square FeetParque Industrial Finsa Santa Catarina 1Servidumbre de Paso #3193 Col. El Palmar Sta.

Catarina, N.L. C.P. 66367

52.81.4739.6900

Holland, MI USA

238,000 Square Feet - Global Headquarters300 E. 48th St. Holland, MI 49423616.820.2500

Suzhou, China

160,000 Square Feet133 Songshan Road Suzhou New DistrictJiangsu Province, China 215129

86.512.66626188

Parts Tailored to Your Specific Needs

Discover how our global brand delivers exceptional results across a range of markets by combining deep draw metal stamping expertise with advanced transfer press, progressive die, and other precision stamping technologies.

Custom Engineered Solutions

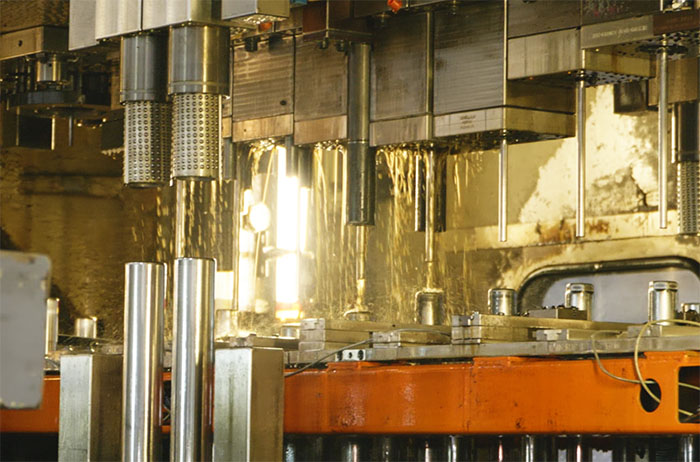

Trans-Matic serves our customers by producing complex, tightly toleranced component parts. We set the standard when it comes to deep draw stamping, and we have spent over 50 years earning our clients’ trust.

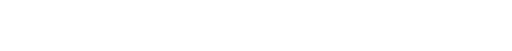

Familiarize Yourself With What We Do

Manufacturers across a range of industries all face the same pressure: produce reliable parts at the right cost, without sacrificing quality. That’s where value engineering plays a critical role. As a global metal stamping manufacturer, we specialize in providing value added services like fully automated assembly, non-destructive testing, and more to help customers get better-performing parts and smoother production from day one.

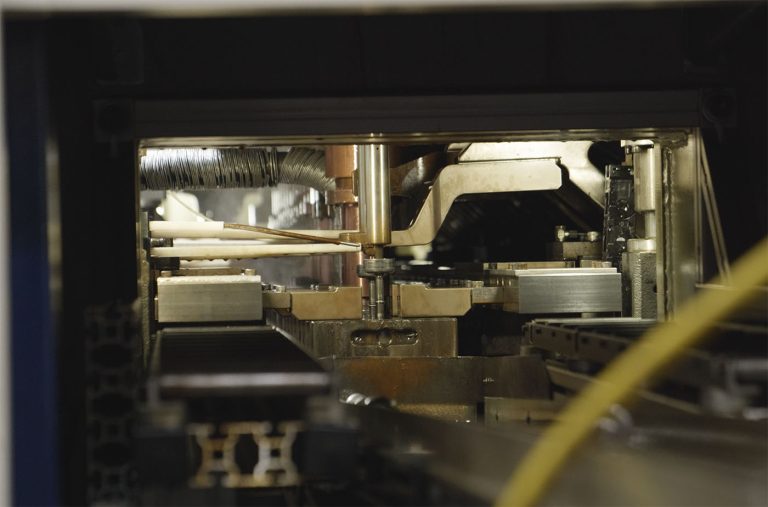

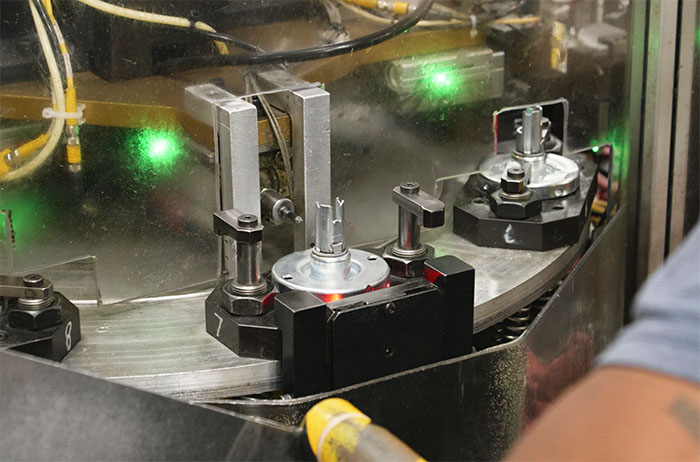

Precision and accuracy are critical to producing high-quality stamped metal parts that meet stringent industry standards. Before scaling up production, however, our metal stamping manufacturer must ensure that each component is precisely engineered to match the specifications required for its application. This is where custom prototyping plays a pivotal role, offering an opportunity to fine-tune designs, test materials, and optimize manufacturing processes.